This is from another website just thought it would be a good DIY here before the other website disappears.

#1 Unplug the connections for the stator wires behind the frame tube next to the CARB.

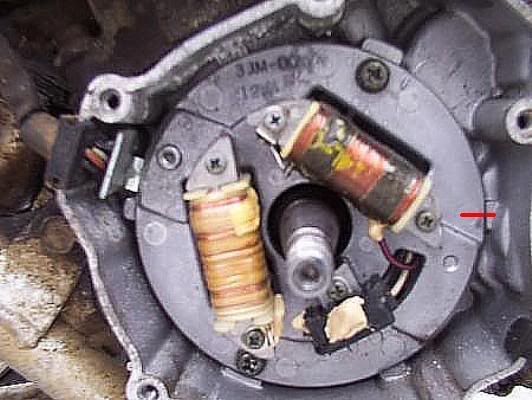

#2 Remove the stator cover

#3 Remove the flywheel and keyway.

#4 Mark the original stator position with a scribe as in the pic (the red line marks the stock timing location)

#5 Next remove the stator plate by removing the two mounting bolts

#6 using a scribe measure and scribe a line 3mm to the left of the mounting hole location. This will give you a 4 degree timing advance

#7 Using a round file or a grinding bit in a dremal tool widen the mounting holes 3mm to the line you just made.

#8 reinstall the stator plate and measure the marks you made in step #4 and make sure the plate can now be turned 3mm.

If you wish you can slot the stator both to the left and right so it's possible to retard the timing for custom applications!