A while back someone asked the question, where all the brotherhood and camaraderie went around here. It left when people who are getting rolling get bashed for being competition.

Ken, if in 1985 someone had "looked in" on your operation, would they have seen the operation it is now? I highly doubt it. Everyone has to start somewhere. I do consider tooling, knowledge, capacity, and repertoire to be "growth", don't you? What do you consider growth, only square footage? I think your definition of growth is severely narrowed by your desire to bash competition any way you can. Also, I previously had my phone number on the website but after finding out that your "cronies" have a tendency to list people's personal information on their local CL in the "M4M" section using doctored photographs (explicit in nature) I pulled it back off. I will wait to add one once I get an actual business line. Thanks for that suggestion. Also, because I choose not to fight back doesn't mean the hornets are harmless. If I were harmless, you wouldn't have nearly the sass mouth you do about it.

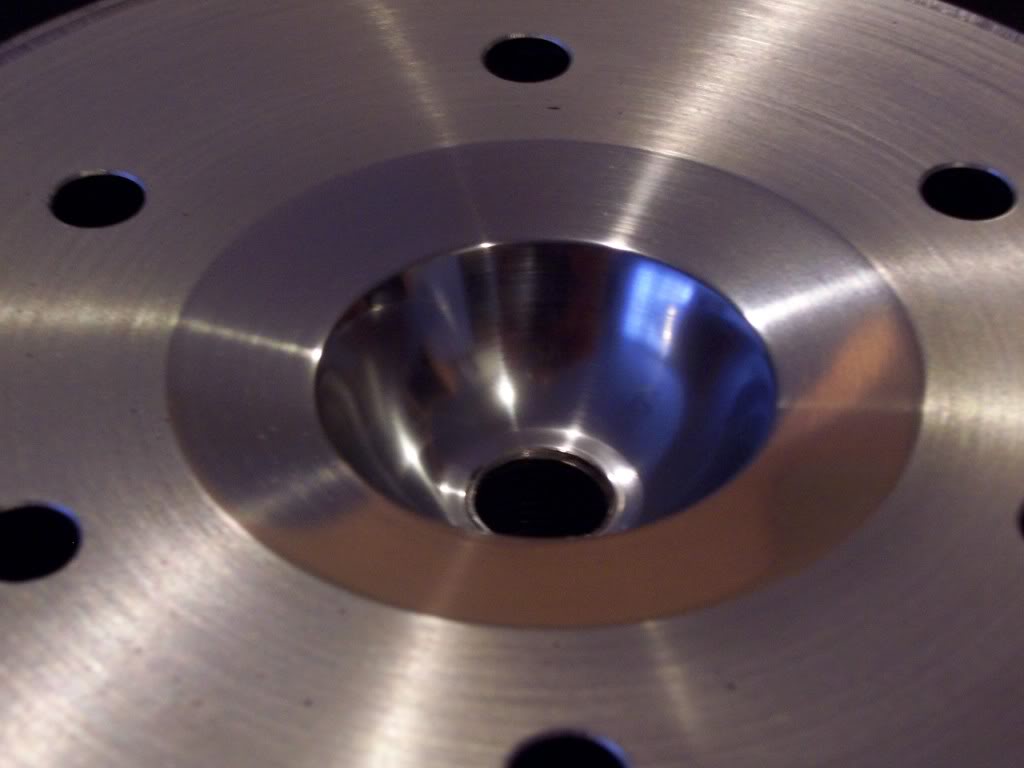

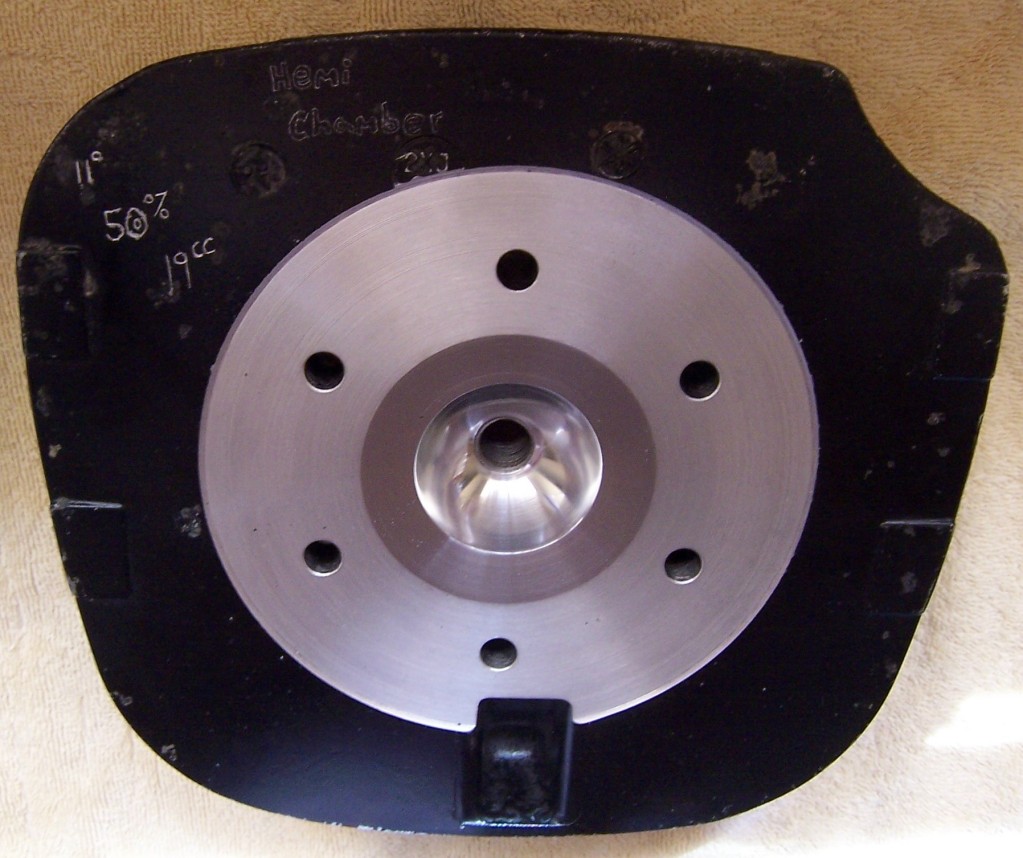

Joeak47, you openly admitted to printing out a picture of a head that I cut and using the printed picture for measurements to cut the head you pictured. You also purchased "sport port" port maps to do the port job. Granted, you did an excellent job on the work (I commended you on the work, at the time too!) but you understood and innovated nothing. You simply copied other people work directly (buying port maps) or indirectly (printing and copying my picture). It's fine bud, everyone has to start out somewhere but heckling someone else while doing far less yourself (innovation and experimentation) isn't wise. You have the skill set to go far but a poor attitude about other people will severely limit your opportunities.

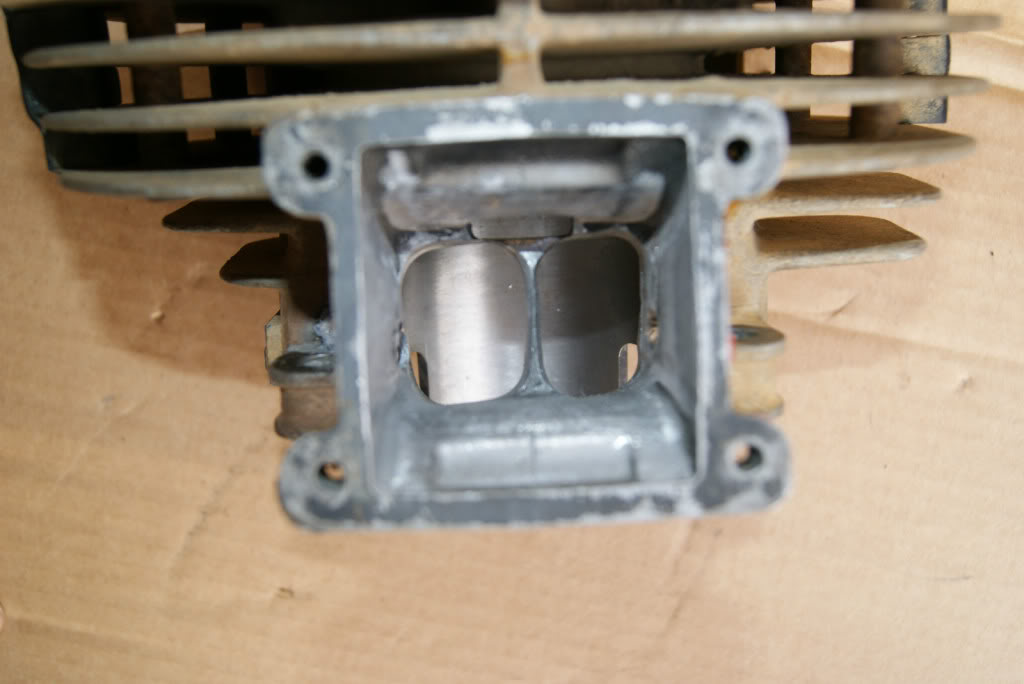

Prime, I flat out told you before assembly to roll it over and check it. Did you? No. How exactly am I supposed to make something right (as I possibly could considering the limited nature of my tooling, at the time!) if you don't tell me its wrong and then run to someone else? Also, after that instance I sent two other people away who were looking to get head work done (based on our conversations about your setup) until I got my Atlas lathe setup after which I contacted YOU about making that right ( I made the contact, remember?) and cutting another head. You flat out refused citing an impending sale on Ebay (which you nearly cost another member their Ebay seller rating over) after you parted out the entire quad. I didn't feel like airing either your or my dirty laundry over the entire affair at the time so I let it slide.

I do appreciate everyone's otherwise positive comments and suggestions. I have been in contact with my lawyer and the State of NC about the best route moving forward. I have been keeping close tabs on costs and profits (LOL joke) for some time now. So far I haven't come out of the red so there isn't much for "the man" to come after anyone for.

Best, long time no see man. Haven't been around a lot for various reasons. I'm not too aesthetically gifted either (as you can see from the design!) but I'm doing in typical SCD fashion and doing it myself and I wouldn't have it any other way!!!!!!!!!

Blaaster, you have to understand.... I didn't take the vast majority of the pictures with the intentions of making them advertisements. They were mostly taken to show folks what was going on so most aren't finished (in progress) or with very good backlighting. As I work I'm getting the photography down a LITTLE better. I still have a major impediment to taking high quality photos.... I do the work in my spare time and not much is left afterwards for being a professional photographer LOL.

About the break-in procedure.... This guy is a little fanatical (he's a believer) but his logic is sound I'd also like to point out that I have never, in all my various incarnations of engines I've had, EVER siezed a top end, thrown a crank bearing, or wallowed out a crankshaft. I have, however, broke in every engine I've had with 3 10 minute IDLE periods, re-torqued, and then beat the CRAP out of them. Chock it upto good luck if you'd like but I'm sticking with it.

Surf and 3mil, thanks guys. I told you not to and you did anyway. That's more than "customers", that's friends.

And I'll close on a few philosophical notes (take them for what they are). Everyone takes it so serious but what did we all come here for? Riding, not internet bench racing. We all have the same passions but we let silly divisions and bickering get in the way of that and for what? profits? macho-ism? internet fame?

How about this, how about we all go out and go rip up some dirt and remember what it's all about?