i starting tearing appart my swingarm bearings to replace them and it seems like there should be a way to grease these things. anyone installed grease fittings into the swingarm bearing area. seems like a good idea. you would have to drill tap and screw them in but would make these bearings last longer i would think.

installing grease fittings into swingarm

- Thread starter Surfrjag

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

good idea, i though of doing it, because my seals didnt hold and let water in, which destroyed everything, and no signs of grease were there.

Blaner

Your Friendly South African Ambassador

hey yeah ive done that, but i actually welded a small nut over a hole i drilled to give the grease nipple more thread so it wont strip...well worth the effort, not that it took much.

Blaner

Your Friendly South African Ambassador

Resurrected thread!!

Larry's Shee was interested in doing this and asked me via PM to post here what i did.

i must first correct myself, i never welded a nut, at the time i posted the above statement, i was unable to remember what i actually did, but i did consider welding a nut at the time i did it, thats y i got mixed up with what i wanted to do and what i actually did!! however, i still have not done so as it doesnt seem like i need to as the nipple is working A-Grade

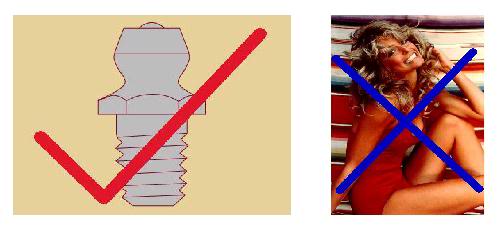

these are just the pics i have of other things like brake hubs etc butyou can see the fitting in them.

I put a small copper washer under the nipple to help it seal. I basically found a nipple, marked where i wanted the hole, measure the thread diamter, drilled a hole the correct size and tapped it out with the right thread.

One small problem is that the metal of the carrier is thinner than the nipple thread is long, so it protrudes into the carrier. the issue is that there is a tube that fits inside the carrier between the bearings. snd this thread hits it. So, you have to file the thread of the nipple to make it shorter, just enough to allow the tube in without the thread hitting it.

Also, when you are pumping the grease in, be VERY careful to do it gently as not to put out your seals. My dad actually suggested i make a small weep hole in the carrier as well near the edge that the grease will squirt out of so i know when to stop.

I hope this helps all!

lastly, dont get confused!

Larry's Shee was interested in doing this and asked me via PM to post here what i did.

i must first correct myself, i never welded a nut, at the time i posted the above statement, i was unable to remember what i actually did, but i did consider welding a nut at the time i did it, thats y i got mixed up with what i wanted to do and what i actually did!! however, i still have not done so as it doesnt seem like i need to as the nipple is working A-Grade

these are just the pics i have of other things like brake hubs etc butyou can see the fitting in them.

I put a small copper washer under the nipple to help it seal. I basically found a nipple, marked where i wanted the hole, measure the thread diamter, drilled a hole the correct size and tapped it out with the right thread.

One small problem is that the metal of the carrier is thinner than the nipple thread is long, so it protrudes into the carrier. the issue is that there is a tube that fits inside the carrier between the bearings. snd this thread hits it. So, you have to file the thread of the nipple to make it shorter, just enough to allow the tube in without the thread hitting it.

Also, when you are pumping the grease in, be VERY careful to do it gently as not to put out your seals. My dad actually suggested i make a small weep hole in the carrier as well near the edge that the grease will squirt out of so i know when to stop.

I hope this helps all!

lastly, dont get confused!

Blaner

Your Friendly South African Ambassador

I must also say that i have stripped the carrier about a year since i put the nipple in to do an axle swap and the bearings were still perfect, no signs of water or rust, exactly how i left them.

Yep, a very good idea. And easy to do. Drill, 6mmx1.0 tap, grease zerk. Most expensive piece is the tap. Took me all of 5 min to install mine. Next time I will put two in spaced closer to the bearings.

Blaner

Your Friendly South African Ambassador

Yep, a very good idea. And easy to do. Drill, 6mmx1.0 tap, grease zerk. Most expensive piece is the tap. Took me all of 5 min to install mine. Next time I will put two in spaced closer to the bearings.

im not sure 2 is necessary, i mean the idea is to pump the chamber full of grease to keep water out and lube the bearings, so the whole chamber will be pressurized upon pumping grease in, so both bearings will be innundated with grease from one.its not like there is anything seperating the bearings.

Another tip, when installing new bearings, pry out the bearing inner face seal so that the grease can get inside the bearing race.

At first I'm like god dang it cause it had some rust then I'm like now I gotta buy seals. but I did this exact same thing on friday only I took it all apart to see how bad my left side bearing was. Pumped the grease in and no more problems what so ever now and saved the seal. Ya I'm glad to see other people are doing this.

Actually this thread came up on search for swingarm I:I . I was actually looking to put zerks for swingarm not carrier  . But it's all good. Decided that probably wouldn't have Blasturd long enough to ever need bearings again, not that hard to do anyways. Lots of grease and anti-sieze and it should come apart just as easy 10 yrs from now

. But it's all good. Decided that probably wouldn't have Blasturd long enough to ever need bearings again, not that hard to do anyways. Lots of grease and anti-sieze and it should come apart just as easy 10 yrs from now  B)

B)

^^^^^^

Yep, got two tubs of grease, grease gun with multible tubes, can of anti-seize, dielectric grease. I'm ready. lol

Yep, got two tubs of grease, grease gun with multible tubes, can of anti-seize, dielectric grease. I'm ready. lol

I put some in mine on the recent tear down. Have to be careful where you place them. The one on the right on mine just barely clears the engine when the suspension is compressed. I put 90 degree ones so you can get to them easier from the side.

Last edited:

Similar threads

- Replies

- 12

- Views

- 3K

- Replies

- 21

- Views

- 3K