SO we all have these recommendations about "squish" or "quench" areas but there seems to be quite a lot of speculation or guesstimation going on about what's the "right" amount and why.

The rule of thumb is as follows: on a trail motor .050" between the piston crown and TDC and the surface of the head squish area is "about right" but why?

First, lets get into MSV. What we're talking about is Maximum Squish Velocity and it equates to the fastest you can push fuel laden air before you excite it enough to explode on its own. Think about it, fuel and air mixed is a bomb waiting for a hair trigger (the spark plug usually) but pushing it fast enough causes enough molecules to slam together for the ignition to start on its own from friction.

The latest and greatest head design (designed around MSV) results in a small hemispherical combustion chamber centered around the are you WANT to detonate (the spark plug) and tight enough tolerances out away from that to dampen the fire but not SO tight that it ignites the fire itself.

When I say dampen, I mean that the "squish" or "quench" area is designed NOT to burn so that the charge is centered inside the combustion chamber and right around the spark plug.

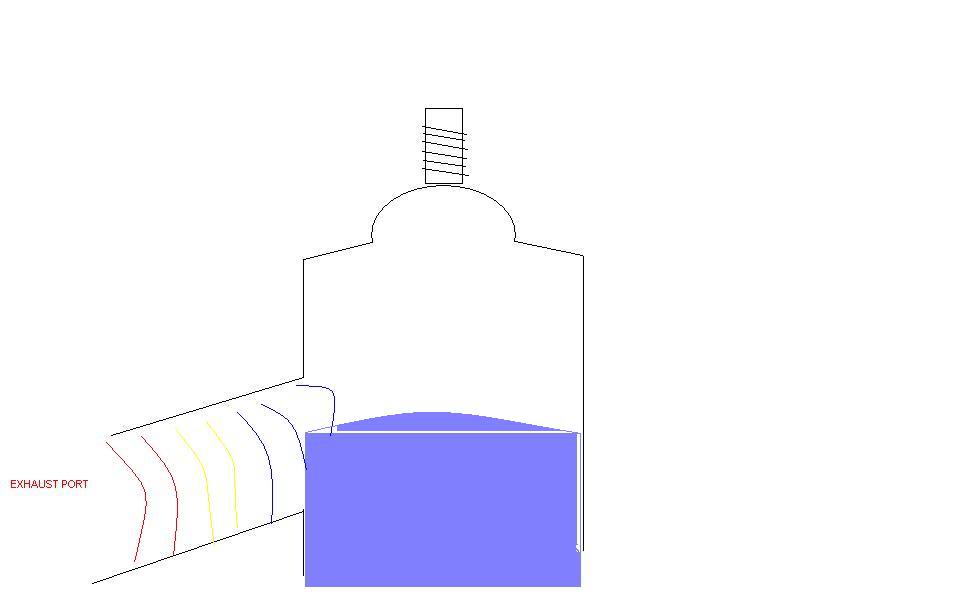

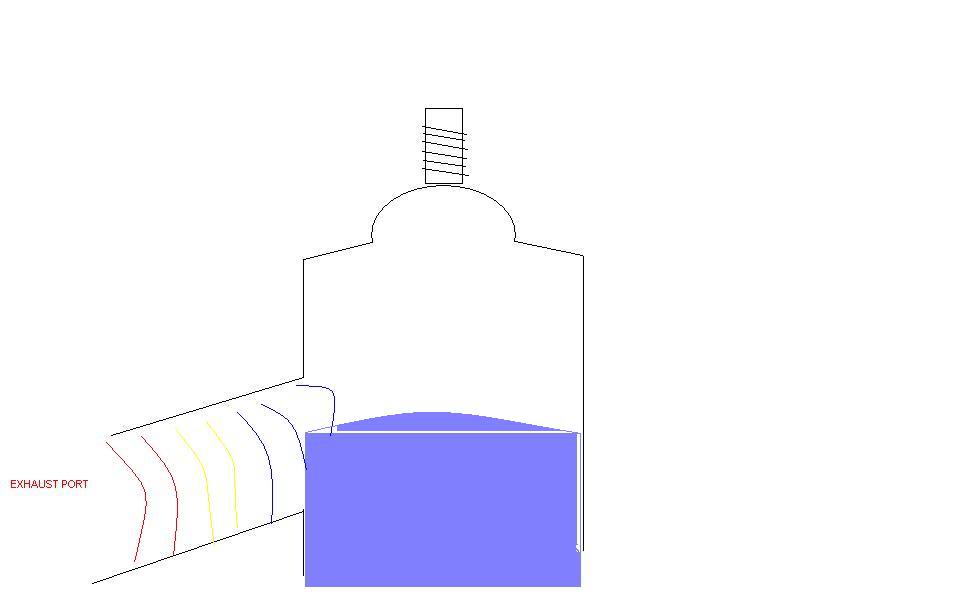

So let's walk through a combustion cycle in a MSV designed head..... It all starts when the transfer ports close (piston coming up) and the volume inside the cylinder is either rushing back in the exhaust port or trapped back inside the combustion chamber already. As the exhaust wave pulse from the tuned pipe does it's job, it rams the charge that has escaped out through the exhaust port back into the port right as the piston closes the exhaust port. This has a mild super charging effect in that the pressure inside the chamber before any piston led compression has taken place is already above ambient (14.7psi at sea level).

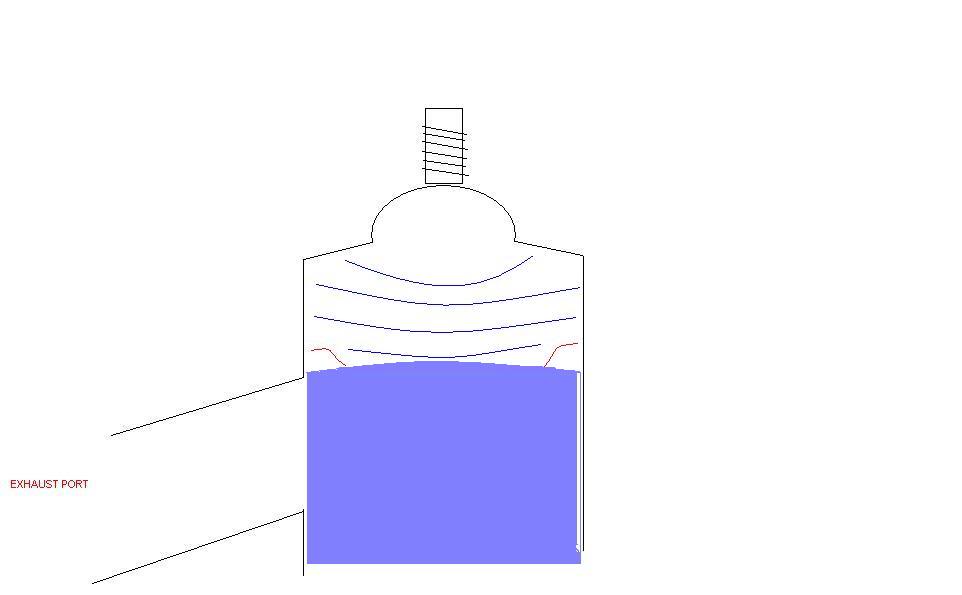

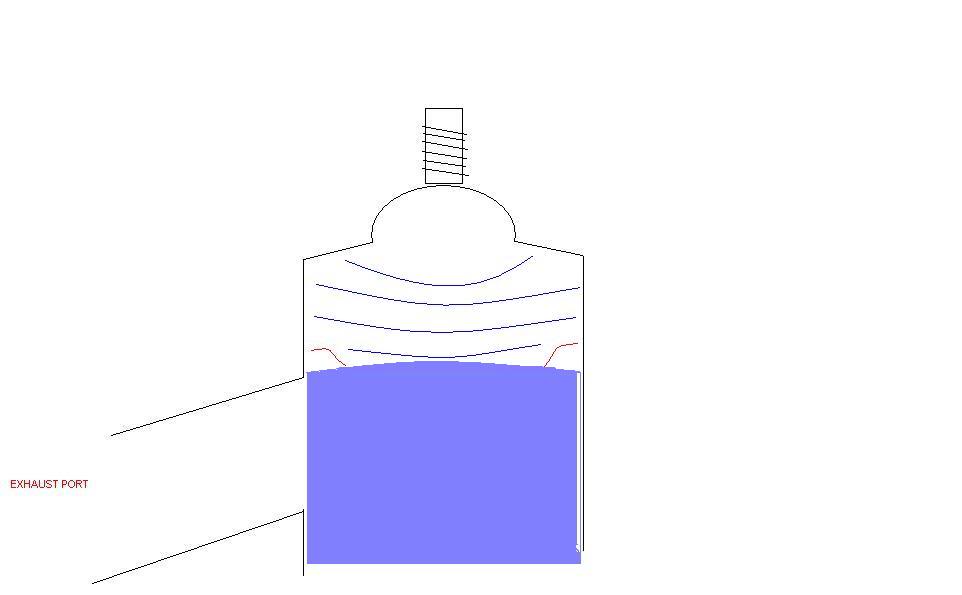

As the piston rises (in the area above the exhaust port) the charge is being compressed. We have homogenized fuel and air (mixed) that is being pushed upwards as the piston rises. This is creating local hot spots (the reason why carbon on the crown is important!) but overall the charge is only gaining pressure and heat as a square of one another.

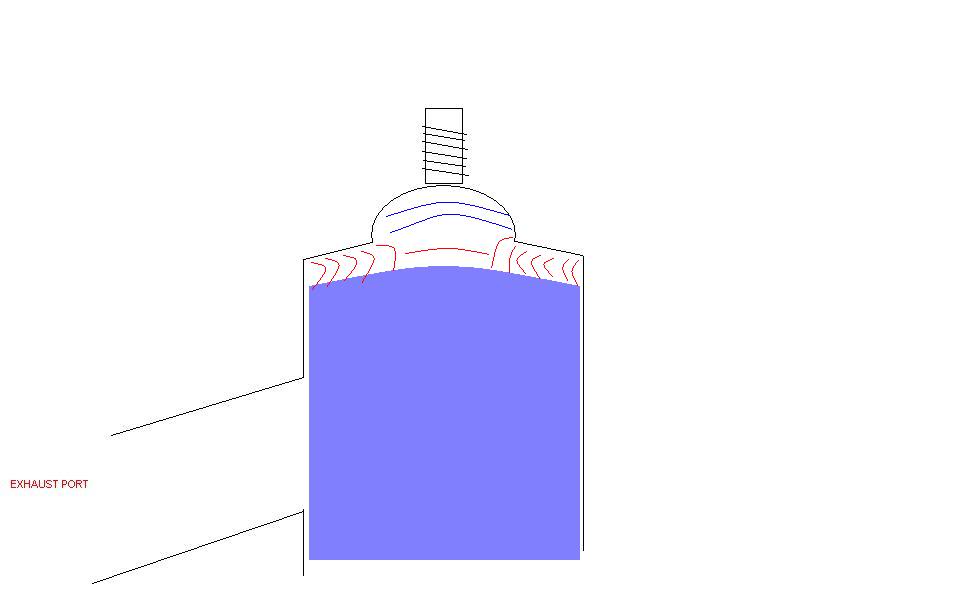

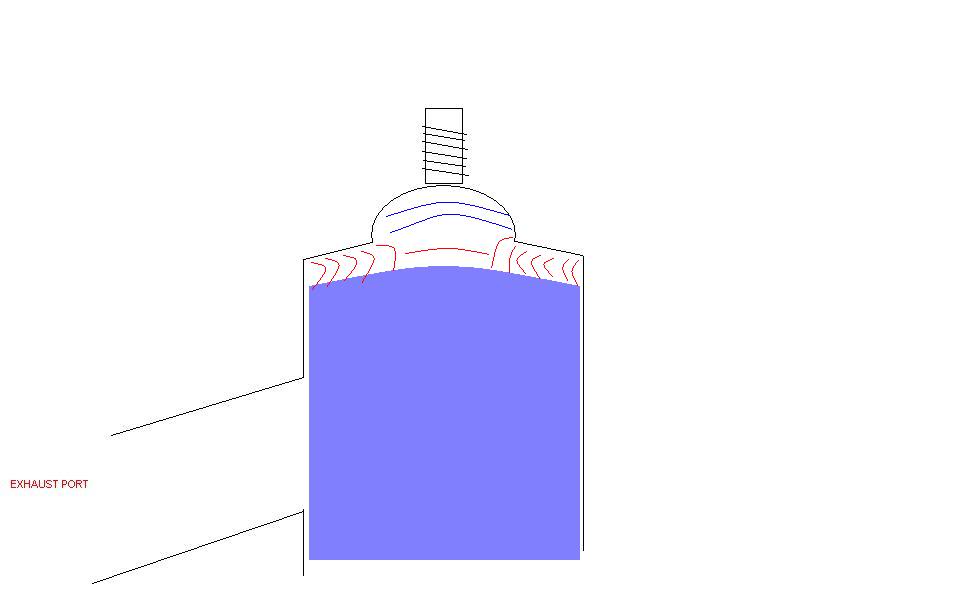

As the piston gets near the top of the stroke, the fuel and air around the outside spikes in temperature and pressure locally as it's pushed between the piston and quench area. This action is the beginning of the REALLY hot charge as the speed of the engine and size of the squish area determine exactly how fast the charge gets pushed in this part of the stroke. It's VERY important not to push the charge too fast during this part, Remember, that charge is a powderkeg at this point and ANYTHING could set it off.

Now here's where the magic of MSV heads really comes to shine.... at a certain point (assuming the charge was never pushed "over the edge" and predetonated) the piston rises close enough to the head surface that combustion actually CANNOT take place. This is the reason why this head design has two different names, squish and quench. One describes the action of pushing the charge towards the spark plug, the other describes what happens at TDC (and the spark event more or less). Once the clearance between the head and piston gets close enough, (generally that sweet spot of .050") the charge is pushed out hard enough that it becomes non uniform inside the chamber. The areas around the outside are no longer suitable for combustion. Also, because there is only a thin layer of charge between two pieces of relatively cool aluminum, more heat is drawn out of the charge (cooling by the head and piston) than is being put in (pushing upwards by the piston). Once that occurs, it's called "dampening" of the fire out in the squish area.

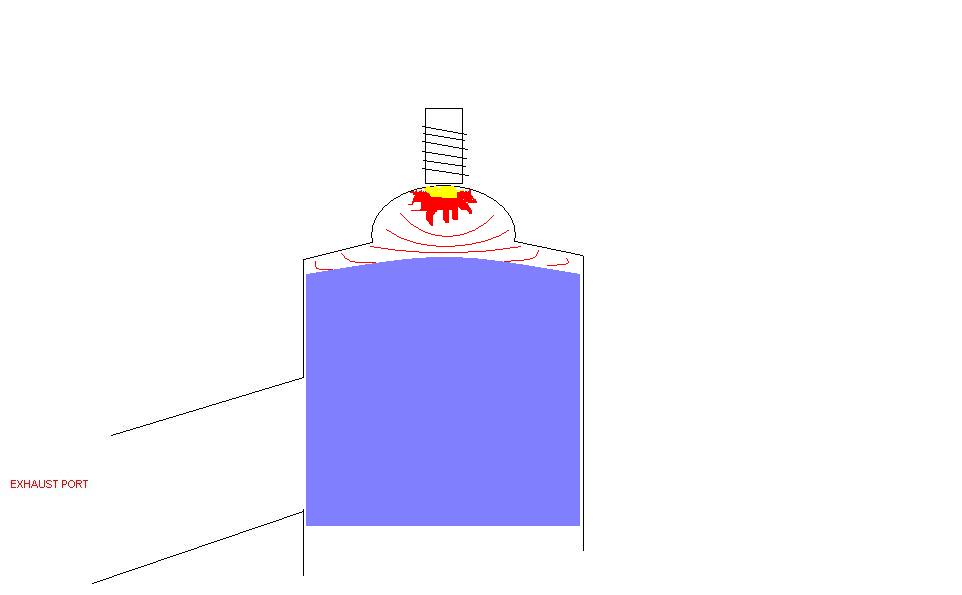

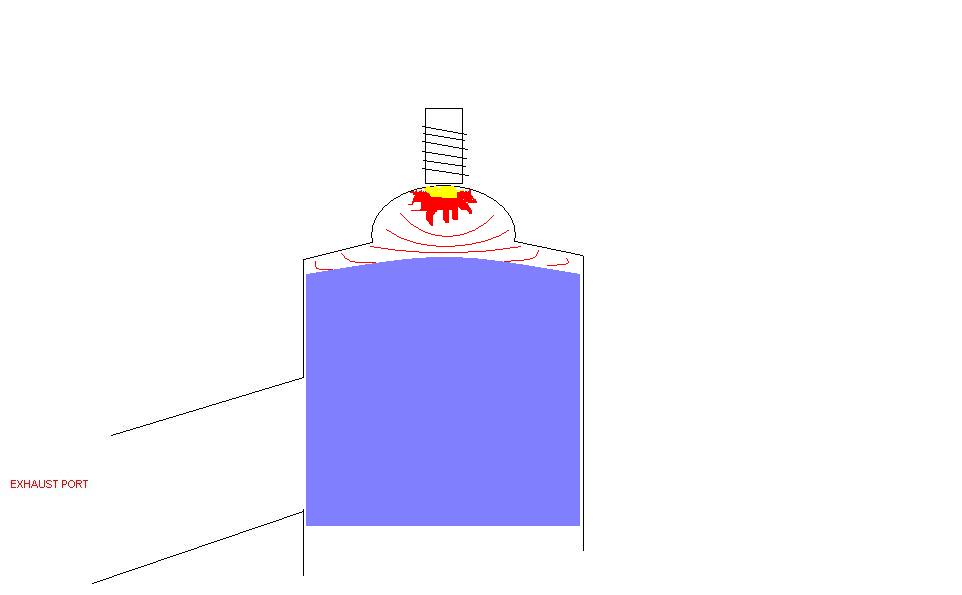

Then it brings us to the ignition event. What we all came for.... The spark plug fires and all that fresh charge that was just pushed in towards the spark plug all explodes with the fireball growing out away from the electrode of the spark plug as a flame front.

This flame front pushes out and down as the pressure rises exponentially pushing down on the piston and crank (and out eventually towards the wheels!). As the flame reaches the edge of the hemispherical bowl shaped combustion chamber, it has to "roll" out around the edge of the squish area. This is why the "break" or edge angle is actually fairly important.....

The rule of thumb is as follows: on a trail motor .050" between the piston crown and TDC and the surface of the head squish area is "about right" but why?

First, lets get into MSV. What we're talking about is Maximum Squish Velocity and it equates to the fastest you can push fuel laden air before you excite it enough to explode on its own. Think about it, fuel and air mixed is a bomb waiting for a hair trigger (the spark plug usually) but pushing it fast enough causes enough molecules to slam together for the ignition to start on its own from friction.

The latest and greatest head design (designed around MSV) results in a small hemispherical combustion chamber centered around the are you WANT to detonate (the spark plug) and tight enough tolerances out away from that to dampen the fire but not SO tight that it ignites the fire itself.

When I say dampen, I mean that the "squish" or "quench" area is designed NOT to burn so that the charge is centered inside the combustion chamber and right around the spark plug.

So let's walk through a combustion cycle in a MSV designed head..... It all starts when the transfer ports close (piston coming up) and the volume inside the cylinder is either rushing back in the exhaust port or trapped back inside the combustion chamber already. As the exhaust wave pulse from the tuned pipe does it's job, it rams the charge that has escaped out through the exhaust port back into the port right as the piston closes the exhaust port. This has a mild super charging effect in that the pressure inside the chamber before any piston led compression has taken place is already above ambient (14.7psi at sea level).

As the piston rises (in the area above the exhaust port) the charge is being compressed. We have homogenized fuel and air (mixed) that is being pushed upwards as the piston rises. This is creating local hot spots (the reason why carbon on the crown is important!) but overall the charge is only gaining pressure and heat as a square of one another.

As the piston gets near the top of the stroke, the fuel and air around the outside spikes in temperature and pressure locally as it's pushed between the piston and quench area. This action is the beginning of the REALLY hot charge as the speed of the engine and size of the squish area determine exactly how fast the charge gets pushed in this part of the stroke. It's VERY important not to push the charge too fast during this part, Remember, that charge is a powderkeg at this point and ANYTHING could set it off.

Now here's where the magic of MSV heads really comes to shine.... at a certain point (assuming the charge was never pushed "over the edge" and predetonated) the piston rises close enough to the head surface that combustion actually CANNOT take place. This is the reason why this head design has two different names, squish and quench. One describes the action of pushing the charge towards the spark plug, the other describes what happens at TDC (and the spark event more or less). Once the clearance between the head and piston gets close enough, (generally that sweet spot of .050") the charge is pushed out hard enough that it becomes non uniform inside the chamber. The areas around the outside are no longer suitable for combustion. Also, because there is only a thin layer of charge between two pieces of relatively cool aluminum, more heat is drawn out of the charge (cooling by the head and piston) than is being put in (pushing upwards by the piston). Once that occurs, it's called "dampening" of the fire out in the squish area.

Then it brings us to the ignition event. What we all came for.... The spark plug fires and all that fresh charge that was just pushed in towards the spark plug all explodes with the fireball growing out away from the electrode of the spark plug as a flame front.

This flame front pushes out and down as the pressure rises exponentially pushing down on the piston and crank (and out eventually towards the wheels!). As the flame reaches the edge of the hemispherical bowl shaped combustion chamber, it has to "roll" out around the edge of the squish area. This is why the "break" or edge angle is actually fairly important.....

Last edited by a moderator: