Pt. 3

Alterations: Durations and area

-BE CONSERVATIVE

Let me state this before you read any further. Every builder has a method and a set of numbers they like to see. I got my start by looking at the numbers that others tried and their results. I then modified them to fit my style of porting and though I don't recommend you take anything I have to say as a rule of thumb, this is the way that I've come to find great results for myself. I was very fortunate to have a multiple world record holding builder take me under his wing. Am I as good as KOR, LED, or Flotek? No, but I'm happy with what I can do (as are a few others

)

I always start designing my ports with the exhaust port height. Most exhaust ports are close to 178-182 degrees of exhaust port duration. If I need more top end power, raising the exhaust port will generally shift the powerband to the right. Too much duration will make your powerband peaky. This is in part because of the height difference between the exhaust and the transfers and boost port. I generally widen the exhaust port to around 2-3mm of clearance between the exhaust port and the exhaust side of the mains. I try to keep all of my corners

somewhat rounded unless I don't want to increase duration or if I'm getting too close to the mains. In this case, I'll reduce the radius on the corners just a little. A short life, all out screamer will typically have square ports with a 1mm radius or less on every corner.

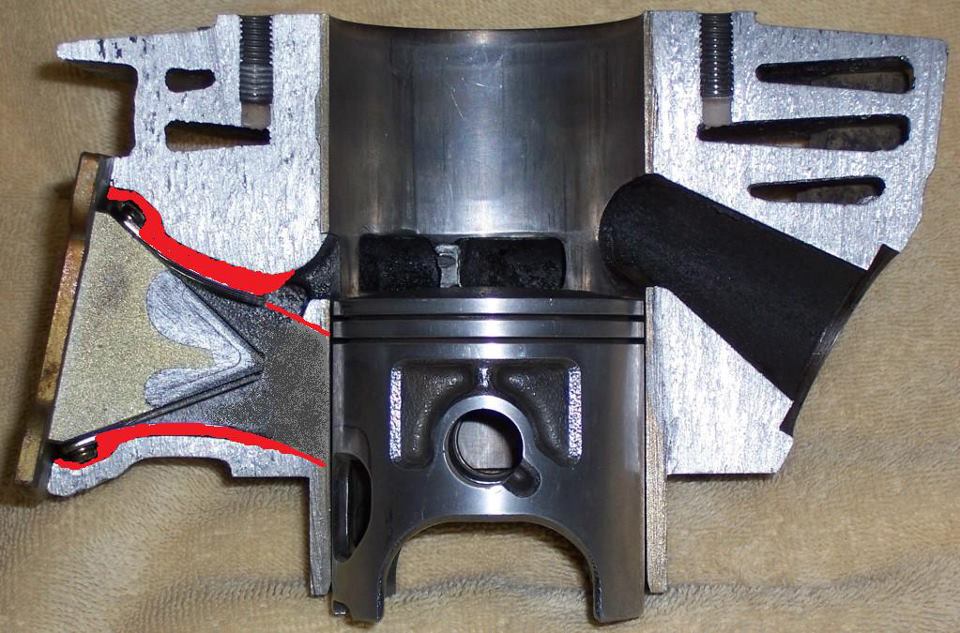

If you're working on a bridged exhaust port, be cognizant of your bridge. If you narrow it too much, you'll reduce the ability of it to shed heat to the surrounding area. This will cause it to bulge into your piston. After honing the cylinder, I like to take 180 grit sand paper to the cylinder on the bridge just for a few seconds to remove enough material to compensate. Again, reducing the radii on the bridge can reduce the ability to shed heat. Be conservative.

Blowdown is the time between exhaust

opening and transfer

opening measured in degrees. I prefer around 28-31 degrees, but don't take that as the golden rule; that's what I like to see. This means that if I have 180 degrees of exhaust duration, I'd like to have 118-124 degrees of transfer timing for a blowdown within my range. Old Suzuki and Yamaha bikes had huge blowdown periods and had gobs of peak power but no power above and below peak. Less blowdown GENERALLY means a wider powerband TO AN EXTENT. Too short and peak power will suffer and over-rev will vanish.

After I have my exhaust duration, I can look at what I want for transfer duration. Say I go with 188 degrees and I want to raise my transfer ports. If I read 132 degrees on my timing wheel, I'll have 28 degrees of blowdown. This puts it within the range that I LIKE TO SEE. If my transfers are at 132, I'll be happy with anywhere from 188-194 degrees of exhaust duration.

Now as stated above, I start with exhaust. After I get that figure and determine whether my transfer ports are within my blowdown preference range, I look at width. My rule for width loosely considers Gordon Jennings's Port-Time Area (PTA) concept. I prefer this a bit more

http://www.dragonfly75.com/motorbike/formulas.html

http://www.dragonfly75.com/motorbike/formulas.html), but still, this is a loose consideration of mine. My largest factor here is the port shape from bottom to top. If I need to grind the cylinder back some to allow for the shape I'm after, I'll reference PTA to ensure that I'm within the limits before I cut.

Staggering the port durations can assist in power spread. If performed improperly, it can ruin the engine (like everything else to do with porting). I don't have very much experience here, but I've seen it done and it does work. I've never seen a difference in staggering of more than 2 total degrees. IIRC, the example that comes to mind is 188 exhaust, 130 main, 132 secondary, 130 boost. Don't go too radical here.

Alterations: shaping

Now, I like to aim my ports as much as possible to the rear of the cylinder. This is for a few reasons. Once all of the AFM piles up at the back of the cylinder, the boost port will help push it upward, purging the cylinder further. Yes, the expansion chamber does the suck and blow thing (haha), but it really blows more below the powerband and sucks too much in over-rev. Aiming the ports rearward will help with filling the cylinder with more AFM and less exhaust (remember the first paragraph?). This will broaden your powerband. From my experience, this doesn't really affect peak power

that much, but it does affect power delivery everywhere else. As for grinding, this may mean removing some material to allow the port to aim the charge in a more desirable path. For you first timers, this can also mean not cutting that one part down to give you that ever so perfect flow divider from some sh*t you saw in a NASA picture. Sometimes, leaving an area alone can allow it to function much better in conjunction with other areas. This goes back to "be conservative".

Now if you consider this for a minute, you'll appreciate an extensive port job much more. If you cut a hole in a piece of paper and blow through it, how well does that path of hot breath stay together and pile up? Not well, huh? Now if you take a piece of tubing and blow through it, you can see that it focuses the path much more effectively. This is why ports that are flatter as a whole while entering the cylinder have more velocity and a wider powerband in general. This takes serious time in most cases.

MacDizzy mentioned this quite a few times on his site. I've also seen a few applications where the outside of the ports were cut through entirely and epoxied over just to accomplish this. From what I've seen, it does work well. The preferred way is to add material to the inside radius and remove from the outside before merging into a flat port.

Now the roof angle matters as well. An angle of 5 degrees on the roof can make a noticeable difference in some applications. I prefer 0-5 degrees on the transfer roofs. A flat roof will contribute more to peak power at higher RPM, while a 3-4 degree roof will spread the power around some. As for the boost port, I've never tried much, but I've never had a reason to. They work just fine like they are stock for me with just port-matching the sleeve to the cylinder. The largest reason that I don't have much experience with boost ports is because I haven't done very much to them before. Maybe KOR or someone else can chime in here.

Lastly, bevel all of your ports. A .5-1mm wide bevel that's .2-.5mm deep has always sufficed for me. Being a little generous with the exhaust bevel is fine.

Side notes:

No explanation as to why, but the builder who taught me said, "no knife edges except occasionally". Sadly, he hasn't explained what fell into the occasionally category quite yet.

Keep structural integrity in mind.

Lots of small changes equals one big change

It's a lot easier to not cut something than it is to put it back. Be conservative.

80-180 grit in a perpendicular direction to travel is great. I always mirror polish my exhaust because I have time 9/10. Otherwise, a 200 grit finish is more than enough.

If you see carbon buildup in the exhaust, flow probably isn't doing too well in that spot.

Power hides within the design of the transfers

If nothing else, remember these 3 things: Be conservative, take your time, don't try to make your tools do something that you can't make them do/they shouldn't do.

I know I missed a lot, but with as much as I wrote, I'm sure there were some typos and holes in explanation.[/QUOTE