so i have a 91 blaster with a fmf header pipe, stock silencer,mikuni vm36 carb and a uni filter with an open top box and my main jet is a 270 my pilot jet is a 35 and the needle clip was set to the 4th slot. i went riding this weekend and it seemed like it was running wayy too rich but this is my first blaster and ive only had it a week there arent any air leaks and the air screw was set at 1.5 turns from seat any other ideas? i feel like ive checked everything and the plug was new

jetting question

- Thread starter blasterb

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

#290 to #300 main.

#32.5 pilot.

Needle in middle slot.

Set the float level, adjust the idle.

Float level should 20 to 21.5mm on a stock carby.

you want to turn the carb and hold it on a slight angle to measure the float height, like shown here......

it should just barely be touching the inner needle, not depressing it,

It is possible to check the fuel level by attaching a length of clear plastic tubing to the drain nipple , lifting it up the side of the carby, and cracking the drain screw.

The fuel should show in the pipe to the level of the carb body above the float bowl gasket.

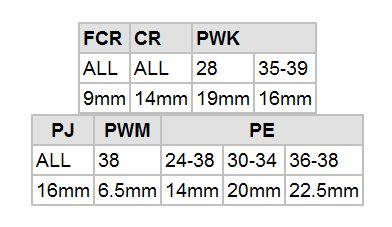

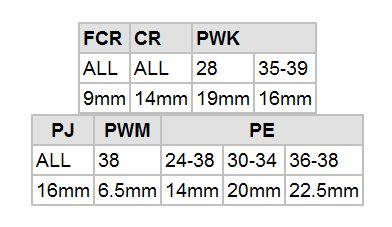

here's the float height's of the most popular carbs run on our blasters.......Credit to Awk08

26mm vm mikuni - 20-21.5 mm (stock carb)

28mm vm mikuni - 22mm

30mm mikuni - 23-25mm

32/34/36 tm mikuni - 18mm

30mm oko - 19-20MM.

keihin carbs -

alot of these float heights came from this website, if your mikuni or keihin carb isn't listed above, it will be listed here.......

Allens Performance Mikuni & Keihin Carbs (mikuni)

Allens Performance Mikuni & Keihin Carbs (keihin)

---------------------------------------------------------------------

Idle adjusting.

Set float level, make sure that all jets are clean and fuel flows freely from the float bowl drain when the screw is cracked open.

Start with air screw 1.5 turns out.

Set idle screw so that it has some sort of idle. With TORS it is the big screw under seat on top of unit. With no TORS is is the brass screw midway down carb body.

Warm up motor and then set idle screw for a faster idle, 2000rpm+

Adjust air screw either way to get the fastest idle.

Adjust air screw a little at a time leaving 10 secs or until the motor responds.

Re adjust idle screw for desired idle .

#32.5 pilot.

Needle in middle slot.

Set the float level, adjust the idle.

Float level should 20 to 21.5mm on a stock carby.

you want to turn the carb and hold it on a slight angle to measure the float height, like shown here......

it should just barely be touching the inner needle, not depressing it,

It is possible to check the fuel level by attaching a length of clear plastic tubing to the drain nipple , lifting it up the side of the carby, and cracking the drain screw.

The fuel should show in the pipe to the level of the carb body above the float bowl gasket.

here's the float height's of the most popular carbs run on our blasters.......Credit to Awk08

26mm vm mikuni - 20-21.5 mm (stock carb)

28mm vm mikuni - 22mm

30mm mikuni - 23-25mm

32/34/36 tm mikuni - 18mm

30mm oko - 19-20MM.

keihin carbs -

alot of these float heights came from this website, if your mikuni or keihin carb isn't listed above, it will be listed here.......

Allens Performance Mikuni & Keihin Carbs (mikuni)

Allens Performance Mikuni & Keihin Carbs (keihin)

---------------------------------------------------------------------

Idle adjusting.

Set float level, make sure that all jets are clean and fuel flows freely from the float bowl drain when the screw is cracked open.

Start with air screw 1.5 turns out.

Set idle screw so that it has some sort of idle. With TORS it is the big screw under seat on top of unit. With no TORS is is the brass screw midway down carb body.

Warm up motor and then set idle screw for a faster idle, 2000rpm+

Adjust air screw either way to get the fastest idle.

Adjust air screw a little at a time leaving 10 secs or until the motor responds.

Re adjust idle screw for desired idle .

thanks, i got it running way better but when i hit wot it just bogs then shuts off if i hold it but if i back it off it runs good again and it would backfire out the exhaust occasionally indicationg a lean condition. so is my 270 main jet just not big enough or what? and also another question is what the heck is that hose on top of the intake? its like a 3/4" hose and is routed to an aluminum can thing it looks like its just been capped on alot of bikes

its called a boost bottle and they are just an airleak waiting to happen

so i can just cap it right? and what is it supposed to even do?

you need to catch us up on what you have done so far ?

taken any of the advice above ?

32.5 pilot ?

checked/set the float height ?

good fuel flow into the carb ?

what position is the needle clip in ?

condition of reeds ?

plug chops on any/all main jets ?

taken any of the advice above ?

32.5 pilot ?

checked/set the float height ?

good fuel flow into the carb ?

what position is the needle clip in ?

condition of reeds ?

plug chops on any/all main jets ?

Last edited:

so i put a #300 main jet in it and i have wot again but its still backfiring at 3/4-full like its running lean any thoughts? ive tried adjusting the air screw and no matter what i do it still does it

You may need to lift the needle one clip.

The air screw does nothing after 1/4 throttle.

Adjust the float, re-set the idle as per specs, lift the needle one clip and bung in a #310 main jet, that should fix it if it is leak free.

What does plug look like? Have you done any plug read/chop? Was boost bottle in place when you did leak down?

Presume it passed test? What pressure for how long?

Presume it passed test? What pressure for how long?

id recommend you reinstall the stock carb.... without a ported jug or head mod that carb aint gonna give ya much more then a blown up motor by the sounds of it.

you need to catch us up on what you have done so far ?

taken any of the advice above ?

32.5 pilot ?

checked/set the float height ?

good fuel flow into the carb ?

what position is the needle clip in ?

condition of reeds ?

plug chops on any/all main jets ?

i cant get a 32.5 just yet because everywhere around is out of stock and im not sure i wanna order one just yet

float height is good just rechecked

fuel flows free into the carb

needle clip is in the #3 slot

the reeds look brand new

no plug chops yet... but obviously its not getting enough fuel

i lifted the needle to the 4th slot and it bogs.. my local shop didnt have a 310 in stock and i havent ordered oneYou may need to lift the needle one clip.

The air screw does nothing after 1/4 throttle.

Adjust the float, re-set the idle as per specs, lift the needle one clip and bung in a #310 main jet, that should fix it if it is leak free.

What does plug look like? Have you done any plug read/chop? Was boost bottle in place when you did leak down?

Presume it passed test? What pressure for how long?

plug is brownish and dry. havent done a plug chop yet and yes it passed leakdown. it only went down 3 psi in 10 min

this almost seems like an easier option than messing with the big carb that is on it. im getting pretty annoyed with itid recommend you reinstall the stock carb.... without a ported jug or head mod that carb aint gonna give ya much more then a blown up motor by the sounds of it.

If it lost 3 psi in ten mins I would consider that it failed the leak test.

If the plug is brown and dry, you are definatly running too lean, fix it before it fixes you.

Do not consider starting the engine again until your float level is correct, the idle is set correctly, you put in a #32.5 pilot jet and a #310 main jet and you have a full stream of gas from the float bowl drain when you crack the screw open.

See below.

.

If the plug is brown and dry, you are definatly running too lean, fix it before it fixes you.

Do not consider starting the engine again until your float level is correct, the idle is set correctly, you put in a #32.5 pilot jet and a #310 main jet and you have a full stream of gas from the float bowl drain when you crack the screw open.

See below.

.

Last edited:

so i put a 310 in and the topend was a little bit better, so after messing around with it a little i went in the house to do some stuff and when i came out to put it back in the shop i kicked it and it started in 2 kicks and was running ok for about 10 seconds then i heard a crack and it shutoff, no more spark so i pulled the stator cover and i found a flywheel flopping around with the end of the crank in it, it just snapped off so i pulled the crank and it actually turns out that it was a +3mm stroker crank from vitos everything was totally fine except for the crank and flywheel but it makes way more sense as to why it was running lean. i had no idea it was stroked... heres the crank

Attachments

If you were not the one who fitted the flywheel, I would be looking for the guy that over tightened the flywheel or used a rattle gun to get it to stop spinning.

wow

was the flywheel still fully tightened to that crank end ? just trying to rule out a loose flywheel as the cause of the crank end failure.

i'd be calling ken and then vito's to see if they'd warranty it ?

yeah i contacted both and ken helped but vitos is making this super hard and only wants to knock off 10 bucks on a new one... and i have to send this one in...

yeah it wasnt me hahaIf you were not the one who fitted the flywheel, I would be looking for the guy that over tightened the flywheel or used a rattle gun to get it to stop spinning.

vitos is making this super hard and only wants to knock off 10 bucks on a new one... and i have to send this one in...

thats some bullshit !

Similar threads

- Replies

- 2

- Views

- 167