Ported the Blastard today more to follow on it in the engine thread....

here;s some pics: mostly just smooth and remove casting imperfections and smooth the intake , smooth and polish the exhaust...

Rough cut:

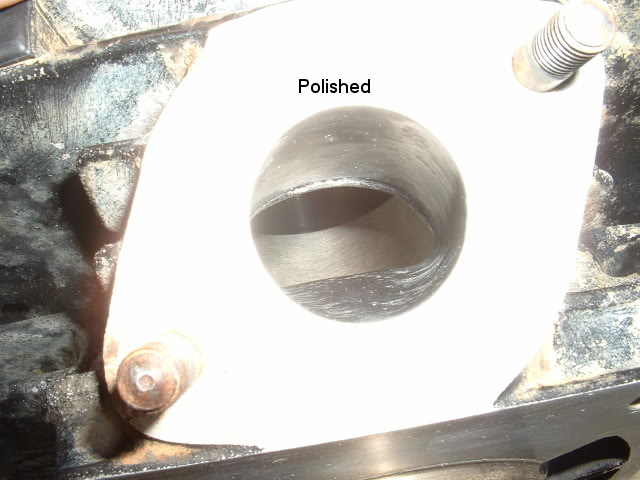

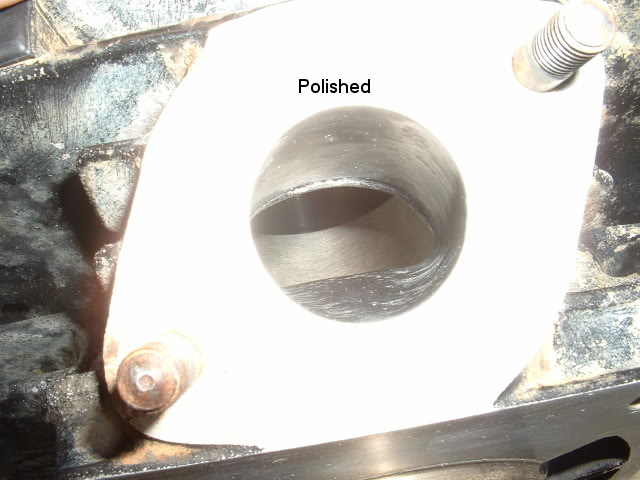

1/2 polished:

Polished and ready to install:

Intake smoothed :

It's all together initial fireup report follows.

here;s some pics: mostly just smooth and remove casting imperfections and smooth the intake , smooth and polish the exhaust...

Rough cut:

1/2 polished:

Polished and ready to install:

Intake smoothed :

It's all together initial fireup report follows.