not sure where you got a 360 jets. I myslelf didnt know they went that high. but maybe they do.

I don't know what that person looked at or did to confirm its not leaking.

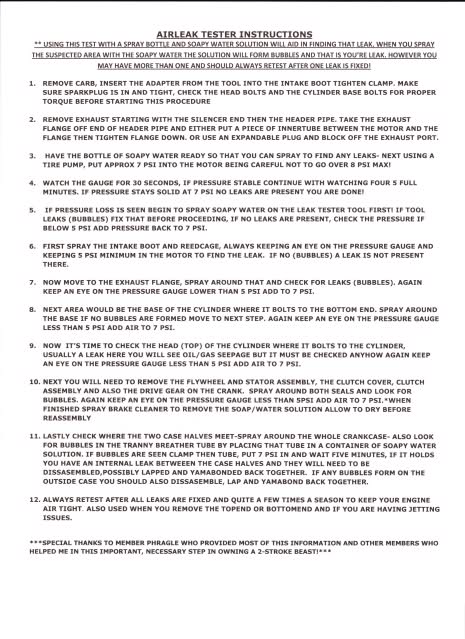

a compression test, does not confirm it does not have a air leak. most air leaks seem to happen in the cases. gaskets to bad crank seals.

I would reocmmend that you follow up and see how they did a leak down test ? what the tool looked like and how it was hooked up.

There are a few things else it could be, but i think until a proper leak down test is done. you might be just passing by what it most important to do now.

If you keep at it, trying to start and run it. you likely will lock it up or blow it up and cause real costly damage to the motor.

However, I will mention some other things 4 you.

replace the spark plug.

cuse cable lube, clean your cables, make sure the throttle cable is not shot or worn out.

confirm the reeds are good and not worn out or damaged.

If you running oil injection and not the block off kit.

clean the tors and slilder

Lower the main jet to a lower number, if indeed you found a 360 and had it installed. to a 260 or 270.

A compression test is not a test, that checks the lower pressure of the crank case. See that pressure, no air leak.

A blaster is a vacuum fed engine. the 2 cycle engine, the ports and wholes in the piston, lower, the post wholes in the piston and cylinder match up in cycle, suck in the gas and oil. puts it into the top of the cylinder, and ect.

A lower end crank case, air leak. would not provide the proper suction of the air flow to pull in the gas and oil.

And if you do fail a proper leak down test, it might not just be the seals, it could be a crack or broken inner case ! or a bad seal with the two case halves.

Sporty