I just got an 02 blaster. I rebuilt the top and bottom end and it is bored 20 over problem is when I start it the rpms go through the roof I tried adjusting the idle screw and air mix screw with no change I've cleaned the carb still no change. Please help

Help please!!

- Thread starter hheath93

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

are you sure the slide in the carb is installed correctly and closing the whole way ?

there is a notch in the slide which must align with the little post inside the throat on the kicker side, and the needle going down into the needle jet

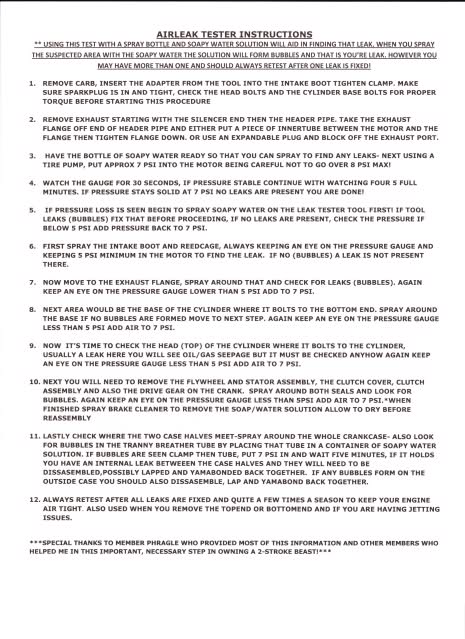

also could be an airleak, which it should have been leakdown tested before ever even starting it anyway

you can find the DIY here.....

http://www.blasterforum.com/do-yourself-20/build-use-leakdown-tester-10663/

or the easy route...

http://www.blasterforum.com/sale-18/leakdown-testers-55015/

there is a notch in the slide which must align with the little post inside the throat on the kicker side, and the needle going down into the needle jet

also could be an airleak, which it should have been leakdown tested before ever even starting it anyway

you can find the DIY here.....

http://www.blasterforum.com/do-yourself-20/build-use-leakdown-tester-10663/

or the easy route...

http://www.blasterforum.com/sale-18/leakdown-testers-55015/

The carb is assembled correctly and the throtle moves correctly also when I move the throtle the rpms skyrocket and linger. Do you think it would have anything to do with needles or jets in the carb since its bored over

The carb is assembled correctly and the throtle moves correctly also when I move the throtle the rpms skyrocket and linger. Do you think it would have anything to do with needles or jets in the carb since its bored over

sounds like a big fat AIRLEAK!

The carb is assembled correctly and the throtle moves correctly also when I move the throtle the rpms skyrocket and linger. Do you think it would have anything to do with needles or jets in the carb since its bored over

if your positive the carb is spotless, all jets were removed and cleaned properly ?....

http://www.blasterforum.com/carburetor-138/how-clean-your-carb-pics-209/

the float height is correct ?.......

http://www.blasterforum.com/carburetor-138/float-heights-how-adjust-them-50565/

and the pilot jet/airscrew setting is correct ?...

http://www.blasterforum.com/carburetor-138/adjusting-your-airscrew-pilot-jet-51060/

then it does indeed sound like an airleak,

it needs leakdown tested if you value the $ you just spent and plan on riding anytime soon

Ok so the copper head gasket had a leak and is now fixed however the throtle response still hangs high. Any ideas?

When you opperate throttle with engine off, can you hear the slide "snap" shut? Have you leak tested? Is the slide cap gasket good? Carb clean? How did you "fix" the gasket?

I can hear the slide snap. I am trying to find a leak tester. The cap gasket looked ok but I will check it again the carb is spotless and I used high temp rtv on the gasket

I can hear the slide snap. I am trying to find a leak tester. The cap gasket looked ok but I will check it again the carb is spotless and I used high temp rtv on the gasket

I would get a new head gasket. Remember you are gambling with that top end you just put in. AWK sells leak testers. You NEED to leak test that motor.

Head gaskets are a one time use unless you anneal it properly before re-use. Never tried it myself.

In the hands of a master annealing a head gasket is a piece of cake.

But get it wrong by not having a large flame to produce an overall even temperature and dropping it on the cold plate other than flat, can result in hard spots in the copper

.If that happens believe me the gasket will leak.

The copper needs to be an even cherry red all over, not easy to obtain with a piddly little flame from a propane torch.

But get it wrong by not having a large flame to produce an overall even temperature and dropping it on the cold plate other than flat, can result in hard spots in the copper

.If that happens believe me the gasket will leak.

The copper needs to be an even cherry red all over, not easy to obtain with a piddly little flame from a propane torch.

Thanks to AWK08 I am certified leak free. I cleaned my carb again now I'm just having trouble getting it to idle

Thanks to AWK08 I am certified leak free. I cleaned my carb again now I'm just having trouble getting it to idle

leakdown ...done I:I

now, in this order....

check/set float height

http://www.blasterforum.com/carburetor-138/float-heights-how-adjust-them-50565/

adjust airscrew/pilot jet

http://www.blasterforum.com/carburetor-138/adjusting-your-airscrew-pilot-jet-51060/

needle on the middle clip position.

get 3-5 jets in the range for your mods, start large and work down with plug chops

http://www.blasterforum.com/carburetor-138/how-plug-chop-53237/

Similar threads

- Replies

- 0

- Views

- 578