i found this article copied and paste i did not write this

idk if im in the right spot but if its wrong ill fix it or ill ask a mod to do it

i found this while browsing the web lol

its for a banshee but thats besides the point

My old man has built and raced just about every type of 2 stroke and 4 stroke bike/atv/car. With 50 yrs of his experiance of tuneing them I asked him some questions.

idk how accurate the info is but i thought it was insightful

Q) why advance timing?

A) By advancing the timing you are igniting the air/fuel mixture a little sooner.

Q) How does this give more power?

A) It takes time for fuel to burn so the spark always fires before the piston reaches TDC. In other words, the spark fires before the piston is finished with the compression stroke. What this does is gets the air/fuel mixture burning and close to maximum combustion pressure at just the right time.

Q) What happens if its not advanced far enough?

A) It fires too late and you lose power.

Q) What happens if its advanced to far?

A) It fires too soon and you get pre-ignition, and possible

sparatic engine rpms.

Q) I run my banshee +5 will it hurt it?

A) Temp,fuel delivery,atmospheric pressure,elevation,compression,stroke,

squash band will be very crucial.If everything is spot on it still may

be very finicky. So modifying timing could cause harm.

Q) You said finicky can you explain that?

A) Remember your altering fuel/air burn time, so adjustments through out the

mixture ranges will be more susceptible to slight changes in,mixture ratio,

type of fuel,heat,elevation,atmospheric pressure,ect.

Q) I have my banshee jetted perfect. I have done plug chop after plug chop

at every rpm range and the plugs look perfect. But I do notice when I am

between 1/16 and 1/8 throttle the engine seems to have a loppy sound,

almost like its miss fireing but when I pull the plugs they look good, any

suggestions to fix that.

A) YUP thats the finicky word i mentioned. If your jetted correct and you

cant get the engine to run smooth all the way through the rpm ranges

drop your timing down 1 degree at a time untill you hit that sweet spot.

I really didnt wanna drop my timing down so I loaded it up and took it to his house. He tor into it changing jets,needles,needle height,. What would get rid of my 1/16 to 1/8 issue would make the throttle responce horrible. So he put everything back to where i had it, and adjusted my timing from +5 to +2

took it out to test it. BAM perfect everywhere.

I now believe that yamaha set the stock timing on the banshee so its less

susceptible to variables. I hope this information helps someone in the future.

And although I might of lost 1/2 to 1 hp I am much happier how smooth it runs throughout the entire rpm range.

he is another again i did not write this its copy and paste

IGNITION TIMING

Combustion of the fuel/air mixture does not happen all at once like an explosion does. It happens as a progressive burning of the fuel, starting from around the spark to the outermost combustion area. When the spark happens in relation to crank degrees before top dead center (°BTDC) of the piston is something that needs to vary according to engine rpm so that maximum combustion pressure of the burning fuel/air mixture happens between 15 and 20 degrees after top dead center (ATDC). That is necessary for the most power to be transmitted to the gears/sprockets/tire. As engine rpm's increase, the amount of time from the piston being at a set amount of °BTDC to being at top center decreases. But the amount of time that the fuel/air mixture needs to burn remains the same (with the exception above 7000rpm when the extra turbulence caused by the squish band shortens the time needed to burn). Going only by this aspect of combustion it would be ideal for the CDI to increase the °BTDC of the timing as the rpms increase, in a linear fashion. This is more or less true for a 4 stroke engine, but for a 2 stroke there are other factors to consider:

1. Since a 2 stroke has combustion once every crank cycle (whereas the 4 stroke combusts once every 2 cycles) then the pistons top temperature can get high enough to melt it at high engine revolutions with the timing advance equal to that of a 4 stroke engine.

2. At high rpms the delivery ratio of fuel/air becomes less and the pumping loss of engine power becomes more with increased timing avance so that it is accumulative enough to weaken engine power at high revs. "Pumping loss" refers to the power detracted from the engine because of the force needed to push the piston up to top center against the pressures of the compressed gases and the pressure caused by gas expansion due to combustion.

3. Making the ignition and combustion happen later at high rpms increases the powerband of the engine equipped with an expansion chamber because the exhaust exiting the exhaust port is still burning and is therefore hotter than it is at lower rpms. That increased exhaust temperature allows the pressure/sound wave to travel faster. A pressure wave that returns to the cylinder sooner than normal better matches when the piston upstroke happens to prevent loss of fuel/air charge out the port. That in effect it allows a wider powerband of engine power.

The following is from Eric Gorr's paper "Basic 2 Stroke Tuning" where he talks about advancing or retarding the whole ignition curve of an advancing/retarding CDI on a dirt bike by changing the stator position CW or CCW:

AFFECTS OF THE IGNITION TIMING

Here is how changes in the static ignition timing affects the power band of a Japanese dirt bike. Advancing the timing will make the power band hit harder in the mid range but fall flat on top end. Advancing the timing gives the flame front in the combustion chamber adequate time to travel across the chamber to form a great pressure rise. The rapid pressure rise contributes to a power band's "Hit". In some cases the pressure rise can be so great that it causes an audible pinging noise from the engine. As the engine rpm increases, the pressure in the cylinder becomes so great that pumping losses occur to the piston. That is why engines with too much spark advance or too high of a compression ratio, run flat at high rpm.

Retarding the timing will make the power band smoother in the mid-range and give more top end over rev. When the spark fires closer to TDC, the pressure rise in the cylinder isn't as great. The emphasis is on gaining more degrees of retard at high rpm. This causes a shift of the heat from the cylinder to the pipe. This can prevent the piston from melting at high rpm, but the biggest benefit is how the heat affects the tuning in the pipe. When the temperature rises, the velocity of the waves in the pipe increases. At high rpm this can cause a closer synchronization between the returning compression wave and the piston speed. This effectively extends the rpm peak [power] of the pipe.

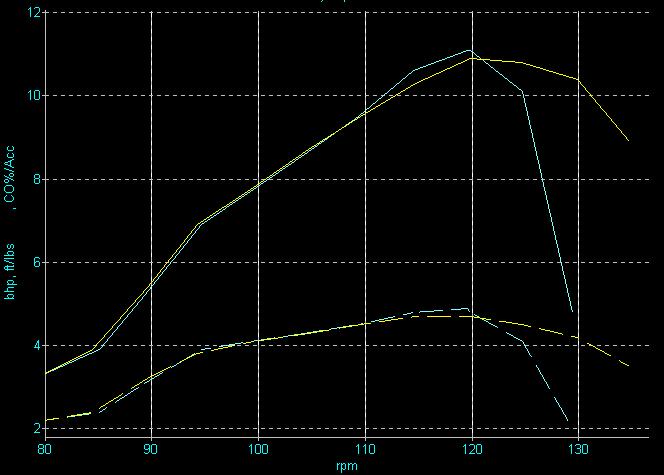

Below is a dyno print of the horsepower difference in a 50cc engine that had the tinming retarded 4 degrees which resulted in the powerband extended 1000 rpm more.

idk if im in the right spot but if its wrong ill fix it or ill ask a mod to do it

i found this while browsing the web lol

its for a banshee but thats besides the point

My old man has built and raced just about every type of 2 stroke and 4 stroke bike/atv/car. With 50 yrs of his experiance of tuneing them I asked him some questions.

idk how accurate the info is but i thought it was insightful

Q) why advance timing?

A) By advancing the timing you are igniting the air/fuel mixture a little sooner.

Q) How does this give more power?

A) It takes time for fuel to burn so the spark always fires before the piston reaches TDC. In other words, the spark fires before the piston is finished with the compression stroke. What this does is gets the air/fuel mixture burning and close to maximum combustion pressure at just the right time.

Q) What happens if its not advanced far enough?

A) It fires too late and you lose power.

Q) What happens if its advanced to far?

A) It fires too soon and you get pre-ignition, and possible

sparatic engine rpms.

Q) I run my banshee +5 will it hurt it?

A) Temp,fuel delivery,atmospheric pressure,elevation,compression,stroke,

squash band will be very crucial.If everything is spot on it still may

be very finicky. So modifying timing could cause harm.

Q) You said finicky can you explain that?

A) Remember your altering fuel/air burn time, so adjustments through out the

mixture ranges will be more susceptible to slight changes in,mixture ratio,

type of fuel,heat,elevation,atmospheric pressure,ect.

Q) I have my banshee jetted perfect. I have done plug chop after plug chop

at every rpm range and the plugs look perfect. But I do notice when I am

between 1/16 and 1/8 throttle the engine seems to have a loppy sound,

almost like its miss fireing but when I pull the plugs they look good, any

suggestions to fix that.

A) YUP thats the finicky word i mentioned. If your jetted correct and you

cant get the engine to run smooth all the way through the rpm ranges

drop your timing down 1 degree at a time untill you hit that sweet spot.

I really didnt wanna drop my timing down so I loaded it up and took it to his house. He tor into it changing jets,needles,needle height,. What would get rid of my 1/16 to 1/8 issue would make the throttle responce horrible. So he put everything back to where i had it, and adjusted my timing from +5 to +2

took it out to test it. BAM perfect everywhere.

I now believe that yamaha set the stock timing on the banshee so its less

susceptible to variables. I hope this information helps someone in the future.

And although I might of lost 1/2 to 1 hp I am much happier how smooth it runs throughout the entire rpm range.

he is another again i did not write this its copy and paste

IGNITION TIMING

Combustion of the fuel/air mixture does not happen all at once like an explosion does. It happens as a progressive burning of the fuel, starting from around the spark to the outermost combustion area. When the spark happens in relation to crank degrees before top dead center (°BTDC) of the piston is something that needs to vary according to engine rpm so that maximum combustion pressure of the burning fuel/air mixture happens between 15 and 20 degrees after top dead center (ATDC). That is necessary for the most power to be transmitted to the gears/sprockets/tire. As engine rpm's increase, the amount of time from the piston being at a set amount of °BTDC to being at top center decreases. But the amount of time that the fuel/air mixture needs to burn remains the same (with the exception above 7000rpm when the extra turbulence caused by the squish band shortens the time needed to burn). Going only by this aspect of combustion it would be ideal for the CDI to increase the °BTDC of the timing as the rpms increase, in a linear fashion. This is more or less true for a 4 stroke engine, but for a 2 stroke there are other factors to consider:

1. Since a 2 stroke has combustion once every crank cycle (whereas the 4 stroke combusts once every 2 cycles) then the pistons top temperature can get high enough to melt it at high engine revolutions with the timing advance equal to that of a 4 stroke engine.

2. At high rpms the delivery ratio of fuel/air becomes less and the pumping loss of engine power becomes more with increased timing avance so that it is accumulative enough to weaken engine power at high revs. "Pumping loss" refers to the power detracted from the engine because of the force needed to push the piston up to top center against the pressures of the compressed gases and the pressure caused by gas expansion due to combustion.

3. Making the ignition and combustion happen later at high rpms increases the powerband of the engine equipped with an expansion chamber because the exhaust exiting the exhaust port is still burning and is therefore hotter than it is at lower rpms. That increased exhaust temperature allows the pressure/sound wave to travel faster. A pressure wave that returns to the cylinder sooner than normal better matches when the piston upstroke happens to prevent loss of fuel/air charge out the port. That in effect it allows a wider powerband of engine power.

The following is from Eric Gorr's paper "Basic 2 Stroke Tuning" where he talks about advancing or retarding the whole ignition curve of an advancing/retarding CDI on a dirt bike by changing the stator position CW or CCW:

AFFECTS OF THE IGNITION TIMING

Here is how changes in the static ignition timing affects the power band of a Japanese dirt bike. Advancing the timing will make the power band hit harder in the mid range but fall flat on top end. Advancing the timing gives the flame front in the combustion chamber adequate time to travel across the chamber to form a great pressure rise. The rapid pressure rise contributes to a power band's "Hit". In some cases the pressure rise can be so great that it causes an audible pinging noise from the engine. As the engine rpm increases, the pressure in the cylinder becomes so great that pumping losses occur to the piston. That is why engines with too much spark advance or too high of a compression ratio, run flat at high rpm.

Retarding the timing will make the power band smoother in the mid-range and give more top end over rev. When the spark fires closer to TDC, the pressure rise in the cylinder isn't as great. The emphasis is on gaining more degrees of retard at high rpm. This causes a shift of the heat from the cylinder to the pipe. This can prevent the piston from melting at high rpm, but the biggest benefit is how the heat affects the tuning in the pipe. When the temperature rises, the velocity of the waves in the pipe increases. At high rpm this can cause a closer synchronization between the returning compression wave and the piston speed. This effectively extends the rpm peak [power] of the pipe.

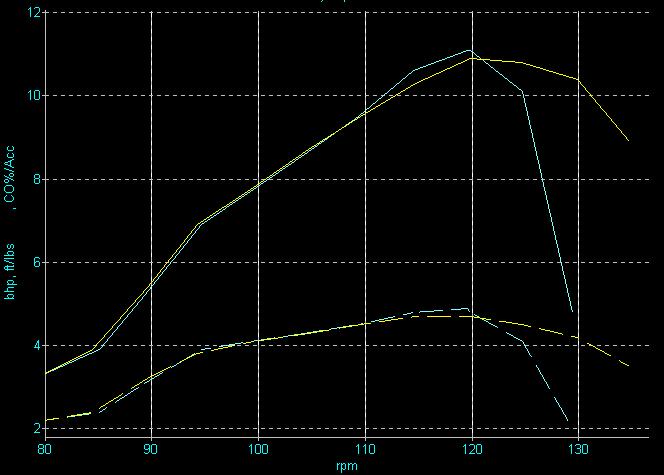

Below is a dyno print of the horsepower difference in a 50cc engine that had the tinming retarded 4 degrees which resulted in the powerband extended 1000 rpm more.