good evening

thank you very much, i am still new at this sorry for the stupid question what does AFR stand for, and how can i determine if it is pre ignition? at this stage i thing the mix is a bit to rich as the bike is smoking quite a bit even when hot.

thanks again have a good evening

Air/Fuel Ratio.

You should plug chop to see if the AFR is correct.

Is the smoke white and stinky?

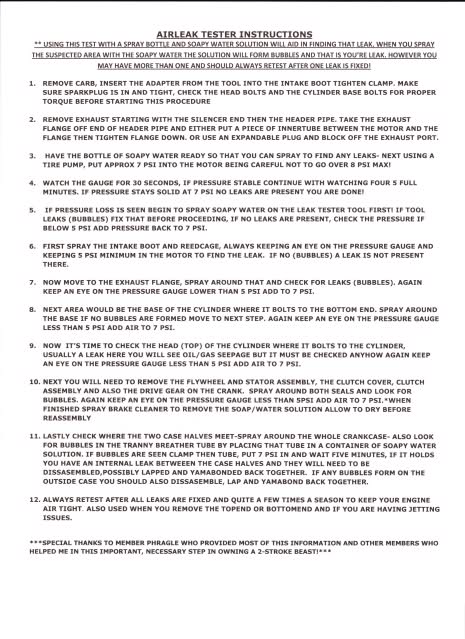

The smoke could be caused by a leaky crankshaft seal allowing air and oil into the crankcase.

A leaky seal can upset the AFR.

Do these things...............................................................

Before you make the plug chop run it is important that the float level is correct, the idle is set correctly and there are no air leaks in the system, otherwise the smoke ring may lie about the AFR.

WHEN ALL OF THE ABOVE ARE CORRECT PROCEED WITH THE FOLLOWING.

Warm up motor to operating temp.

Fit new B8ES plug, ride WOT through the gears and hold WOT in 5th or 6th gear for 10 seconds, or as long as you can safely.

Switch off the motor and pull in the clutch, apply brakes to come to a stop quickly.

Take the plug out and replace the old one for the ride home.

Carefully cut the threaded end off the plug to expose the insulator.

There should be a smoke ring of a cardboard or biscuit colour around the insulator.

If it is non existant or a very light colour, you are lean and require a larger main jet.

If it is a lot darker you are rich and may go down a size in main.

I prefer to run a little on the darker side, I may loose a little power but it is worth it for the peace of mind that I won't need a rebuild so soon.

http://www.blasterforum.com/do-yourself-20/how-plug-chop-38674/

http://www.blasterforum.com/engine-13/plug-chop-how-vid-48226/

This is a good to go plug.

This one is a little rich, but I would run it, I like to be on the safe side.

You have to get up a reasonable speed so that you can get the motor to pull strongly.

Then hold it Wide Open Throttle (WOT) for 10 secs or as long as you can.

The idea is not to get speed but to make it pull strong at full throttle to get onto the main jet circuit.

I find I can safely do it on a short run by applying the brakes some.

If you have not enough room you can use 4th or 5th gear with good results.