I have been quiet for some time, and contrary to popular belief, I have not given up on the good ol blaster, but instead have spent many hours finding ways to better the machine. Many a late night and cups of coffee have passed to bring you a new creation!!!

as some of you may recall, Frankenblast was put into storage after a series of series breakdown. It all started when I had a catastrophic rear swingarm failure in the middle of nowhere. http://www.blasterforum.com/threads/broken-swingarm.61538/ Once I got that all patched up and reinforced, I tackled another tough ride which saw my rear spring go flying out, almost decapitating fellow riders behind me as my rear shock snapped clean in half. The shock damage was as a result of it being bent when the swingarm snapped the 1st time. http://www.blasterforum.com/threads/rear-suspension-woes.61996/

All of that was in April 2015. Almost a year ago...

Since then, I have been scratching my head, thinking of different ways to design a new one. Playing with rectangular tubing and even dabbling in roundhouse carrier designs....http://www.blasterforum.com/threads/new-swingarm-design.61795/#post-770553

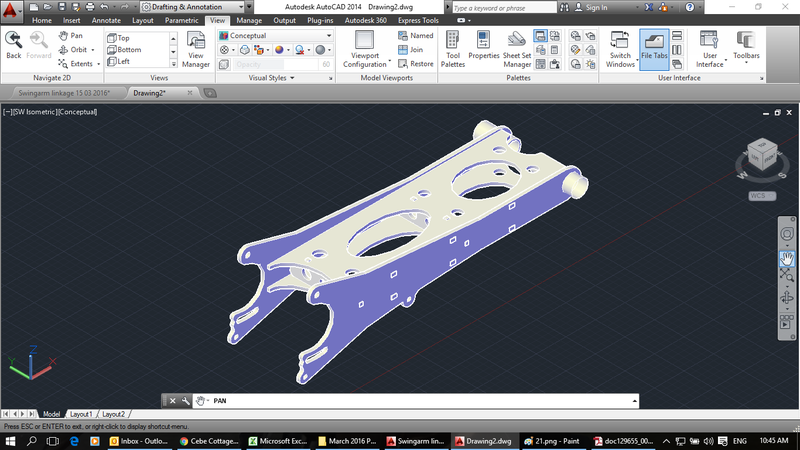

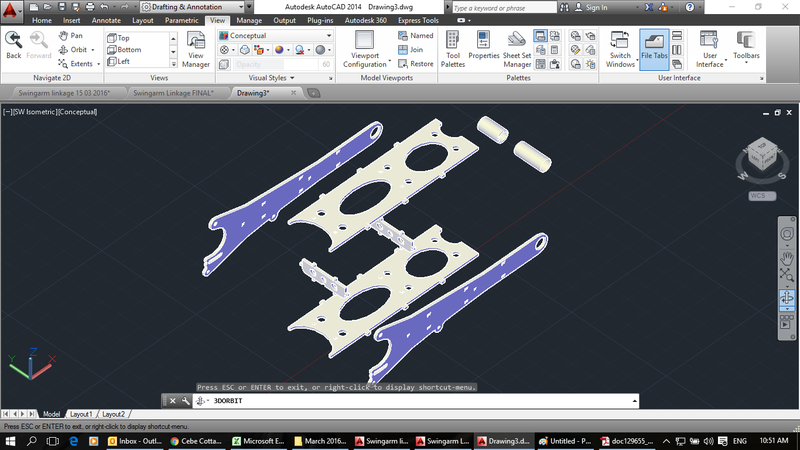

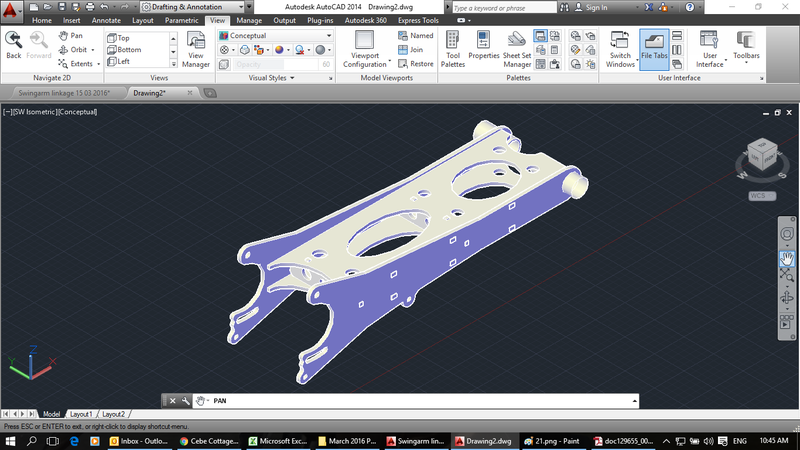

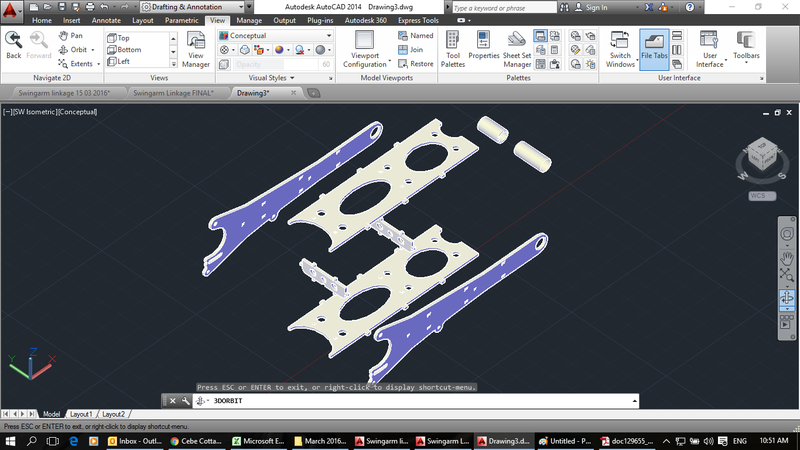

I have finally just sent off the DWG files to the laser cutters to get the parts I need for my new design cut. I have decided to try a YFZ450 Linkage and rear shock system. Its complicated, but armed with measuring devices ranging from inclinometer cell phone apps to spirit levels and vernier calipers, all the measurements where gathered. I used my brothers 450 as a template again. As I did on the front suspension swap.

My new design employs the use of flat steel plate rather than hollow tubing. The advantage of this is that you get away from 90° bends, which are inherent with square and rectangular tubing. I plan to use 6mm steel throughout, which will also allow for stronger welds without the risk of burning through as on tubing.

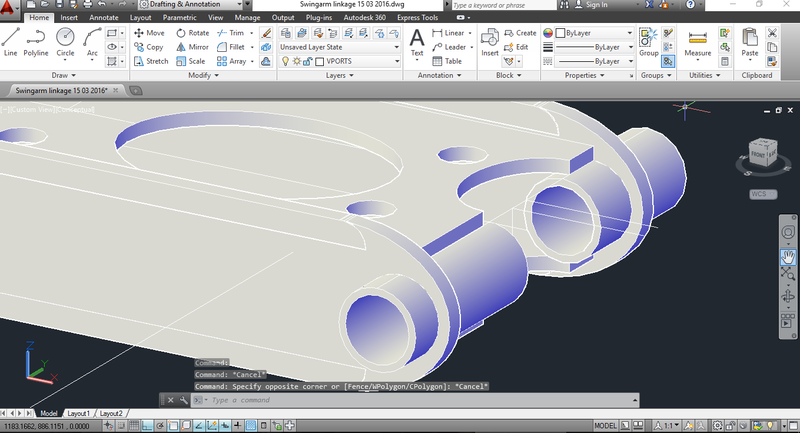

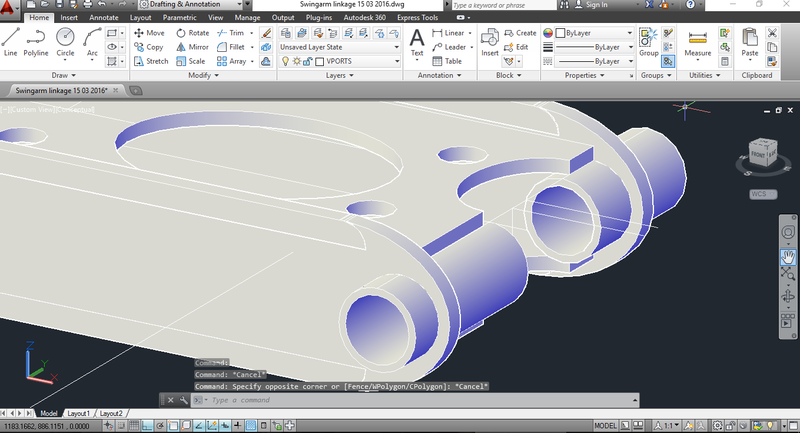

I will have the front bearing tubes machined again, but this time, il keep them as one piece, joined together to make it easier to align when welding. Once welded, il just cut the joining bit out.

Wheres the shock mount? I hear you ask...good question...the 450 linkage system attaches to the base of the bike frame, to a fixed point on the swingarm and to the bottom of the shock. As the base of the frame mount will be added and positioning of this is limited, and the bottom shock mount is located, well at the bottom of the shock, (which lies at a 70° angle) the variable is the point where the linkage attaches to the underside of the swingarm. This is then a simple case of finding the correct position for this once the swingarm is installed and the bike is set to the correct ride height. All i will do is weld a cross bracket with some ears on it in the correct position.

I have allowed for the shock (Diam = 70mm) to pass through the swingarm through an ellipse of 90mmx 120mm. I have also used the 450 design to influence my cutouts, like the ellipse shape at the back for weight saving and more importantly, access to weld on the inside.

I then decided, on the advise of a friend, the key the pieces, to allows them to "clip" together. This will aid assemble, eliminates the need for a jig and will give good weld point.

A roundhouse carrier design went out the window with the Rand. Our currency has fallen badly recently and a billet carrier is just too expensive at this stage, plus, I snapped a piece of metal tubing while my carrier bolts and tensioner system was fine. Its obviously a tough system. Il try it again...

I have sent the parts off, so I hope to have then back soon to get back on the trails again!

There are a lot of construction lines in these pics, so dont worry about them. Please shout if you want a close up or different angle of any pieces.

Il keep you all posted as we go.

Once this is complete, Project WR200 is free to commence.

Stay tuned...

as some of you may recall, Frankenblast was put into storage after a series of series breakdown. It all started when I had a catastrophic rear swingarm failure in the middle of nowhere. http://www.blasterforum.com/threads/broken-swingarm.61538/ Once I got that all patched up and reinforced, I tackled another tough ride which saw my rear spring go flying out, almost decapitating fellow riders behind me as my rear shock snapped clean in half. The shock damage was as a result of it being bent when the swingarm snapped the 1st time. http://www.blasterforum.com/threads/rear-suspension-woes.61996/

All of that was in April 2015. Almost a year ago...

Since then, I have been scratching my head, thinking of different ways to design a new one. Playing with rectangular tubing and even dabbling in roundhouse carrier designs....http://www.blasterforum.com/threads/new-swingarm-design.61795/#post-770553

I have finally just sent off the DWG files to the laser cutters to get the parts I need for my new design cut. I have decided to try a YFZ450 Linkage and rear shock system. Its complicated, but armed with measuring devices ranging from inclinometer cell phone apps to spirit levels and vernier calipers, all the measurements where gathered. I used my brothers 450 as a template again. As I did on the front suspension swap.

My new design employs the use of flat steel plate rather than hollow tubing. The advantage of this is that you get away from 90° bends, which are inherent with square and rectangular tubing. I plan to use 6mm steel throughout, which will also allow for stronger welds without the risk of burning through as on tubing.

I will have the front bearing tubes machined again, but this time, il keep them as one piece, joined together to make it easier to align when welding. Once welded, il just cut the joining bit out.

Wheres the shock mount? I hear you ask...good question...the 450 linkage system attaches to the base of the bike frame, to a fixed point on the swingarm and to the bottom of the shock. As the base of the frame mount will be added and positioning of this is limited, and the bottom shock mount is located, well at the bottom of the shock, (which lies at a 70° angle) the variable is the point where the linkage attaches to the underside of the swingarm. This is then a simple case of finding the correct position for this once the swingarm is installed and the bike is set to the correct ride height. All i will do is weld a cross bracket with some ears on it in the correct position.

I have allowed for the shock (Diam = 70mm) to pass through the swingarm through an ellipse of 90mmx 120mm. I have also used the 450 design to influence my cutouts, like the ellipse shape at the back for weight saving and more importantly, access to weld on the inside.

I then decided, on the advise of a friend, the key the pieces, to allows them to "clip" together. This will aid assemble, eliminates the need for a jig and will give good weld point.

A roundhouse carrier design went out the window with the Rand. Our currency has fallen badly recently and a billet carrier is just too expensive at this stage, plus, I snapped a piece of metal tubing while my carrier bolts and tensioner system was fine. Its obviously a tough system. Il try it again...

I have sent the parts off, so I hope to have then back soon to get back on the trails again!

There are a lot of construction lines in these pics, so dont worry about them. Please shout if you want a close up or different angle of any pieces.

Il keep you all posted as we go.

Once this is complete, Project WR200 is free to commence.

Stay tuned...